TA-FLT6060-8A Series

TA

| Tube Cutting Length | 6000mm/9000mm |

| Z Axis Stroke | 240mm |

| Chuck Type | 220mm/320mm/360mm/520mm |

| Tube Section Shape | Round/Square/Rectangle/Oval/H Type/L Type/I Type |

| Laser Source | IPG/Raycus/Max |

| Laser Power | 1500W — 6000W |

| W Rotation Accuracy | ≦0.05mm |

| Positioning Accuracy | ±0.02mm/m |

| Repeatability Accuracy | ±0.01mm |

| Transmission | Single-drive Rack&Pinion |

| Total Power Consumption | <45KVA |

| Power Supply | 380V 50HZ/380V 60HZ |

Bus Control System Three chucks deisgn, bus control system, Laser head can move to both side of the middle chuck, can realize whole tube cutting. |  Double Supports It is equipped with follow-up support + roller support, which can effectively support the tube in the process of cutting and unloading, ensure the stability and accuracy of cutting. |  Less Waste Three chucks deisgn, in the cutting process, any time the tube will be in stable situation, for any lenght finsihing part will get perfect cutting accuracy. Auto loading/unloading system is optional. |

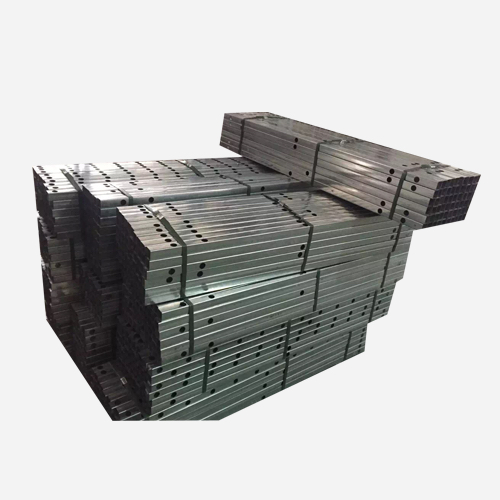

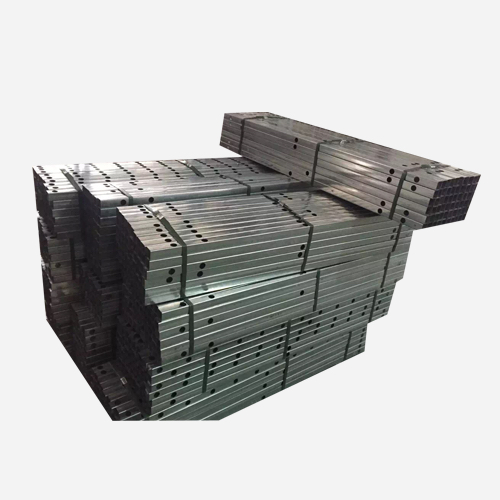

We adopt high rigid carbon square tube welding table, this structure can efficiently solve the issues of shaking and deformation during long time high speed working. It can support mass loading working materials more than 1000kgs. Through twice age process and annealing treatment, protect body will not deformation.

|  |  |

|  |  |

| Tube Cutting Length | 6000mm/9000mm |

| Z Axis Stroke | 240mm |

| Chuck Type | 220mm/320mm/360mm/520mm |

| Tube Section Shape | Round/Square/Rectangle/Oval/H Type/L Type/I Type |

| Laser Source | IPG/Raycus/Max |

| Laser Power | 1500W — 6000W |

| W Rotation Accuracy | ≦0.05mm |

| Positioning Accuracy | ±0.02mm/m |

| Repeatability Accuracy | ±0.01mm |

| Transmission | Single-drive Rack&Pinion |

| Total Power Consumption | <45KVA |

| Power Supply | 380V 50HZ/380V 60HZ |

Bus Control System Three chucks deisgn, bus control system, Laser head can move to both side of the middle chuck, can realize whole tube cutting. |  Double Supports It is equipped with follow-up support + roller support, which can effectively support the tube in the process of cutting and unloading, ensure the stability and accuracy of cutting. |  Less Waste Three chucks deisgn, in the cutting process, any time the tube will be in stable situation, for any lenght finsihing part will get perfect cutting accuracy. Auto loading/unloading system is optional. |

We adopt high rigid carbon square tube welding table, this structure can efficiently solve the issues of shaking and deformation during long time high speed working. It can support mass loading working materials more than 1000kgs. Through twice age process and annealing treatment, protect body will not deformation.

|  |  |

|  |  |

You can contact or visit us in our office from 7:00-17:00